MANUFACTURE

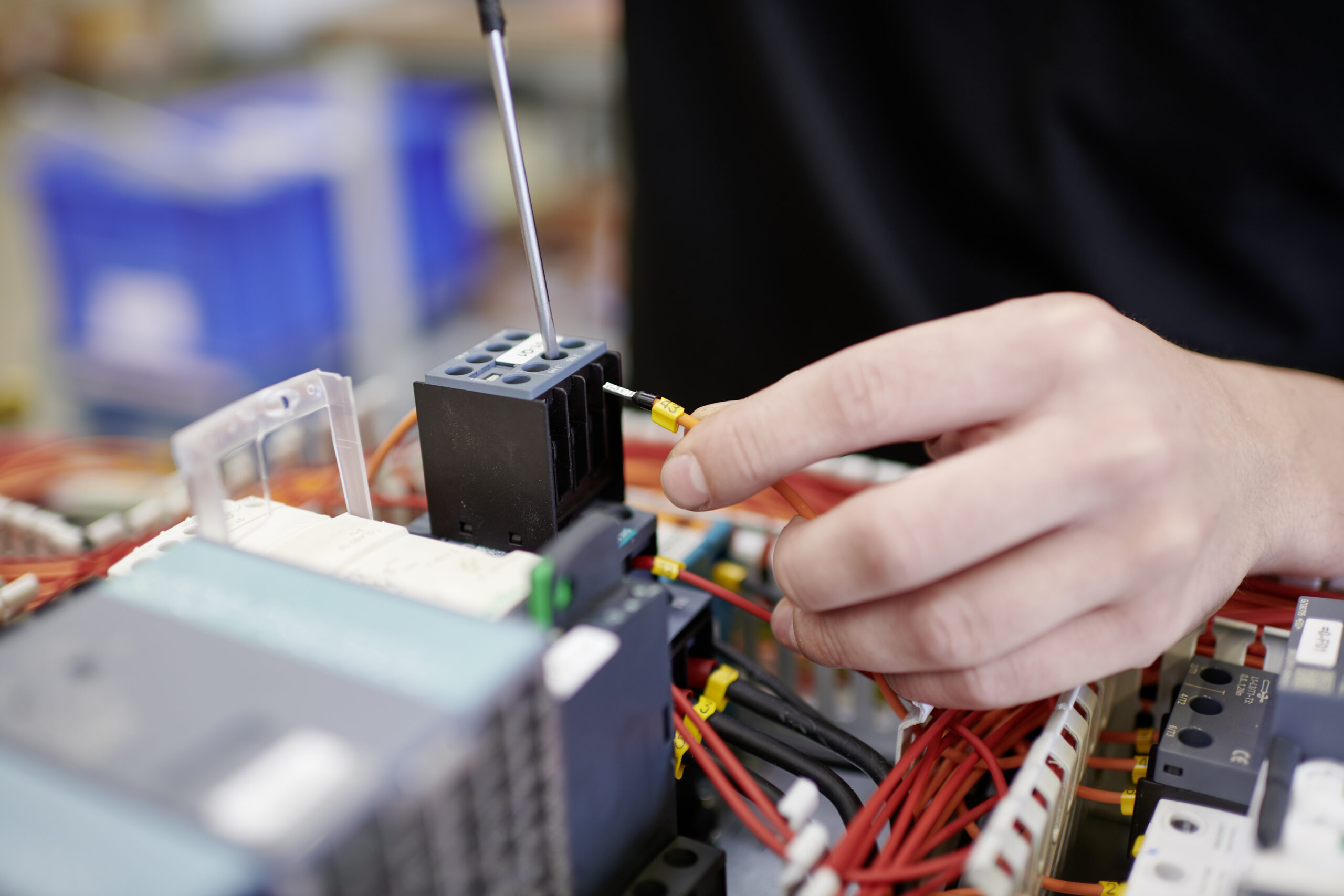

Eye for detail

The preparation and pre-design; the optimization during production as well as the strict adherence to VDE Regulations and DIN Standards are the norm at Plenge, just as is the Functional Testing upon delivery to customers.

Optimization

The Control Cabinets from our Production are configured and manufactured to a variety of customer requirements using optimal production processes and well-tuned warehousing, stockholding and logistical systems as support to the production process.

Production

Automation aids our qualified Electrical Technicians to drastically shorten production times. The design of the Control Cabinet is digitally planned, scheduled and transmitted directly to a fully automated drilling machine.

ADDITIVE:

The Rittal Perforex LC with laser cutting unit takes over the processing of the

Switch cabinet housing and contributes to the diversity and depth of production. The use with the laser machine increases the production speed and effectiveness at a constant high

Plenge quality.

For wiring we use an integrated and semi-automated wiring system called Triathlon®:

- with automatic length calculation,

- optimized cable cutting,

- simultaneous pressing / printing of the ferrules

- and standard-compliant cable marking.

This saves on material and labor and is highly efficient.